With our 24 hour, 7 day-a-week service and maintenance support, customers can be assured that if there is a problem, Endless Belt will quickly be on the scene to minimise costly down-time and get things rolling again.

Onsite Services

- 24-7 Breakdown Service

- 24 hour shift rotations for Planned Maintenance and “Shuts”.

- Installation and repairs of all types of belt

- Installation and maintenance of Belt Cleaning and Tracking Systems

- In-situ Pulley Lagging & Rubber Lining (See Rubber Lining)

- Inspection & maintenance of rollers, pulley & structure

Experienced with:

- Longwall Conveyor Systems

- Flexible Conveyor Train (FCT) Systems

- SICON® systems

- Modular Systems

- Mobile Crushers

Key benefits of Inspection & Maintenance Programs:

- Extend the life and productivity of valuable equipment.

- Reduce the chance of unexpected equipment failure and the consequent downtime.

- Improve the reliability and productivity of equipment

- Prevent expensive after hours service calls by planning maintenance

Workshop Services

- Endless Belts with hot, cold or mechanical joins.

- Underground mine belt reclamation

- Belt assessment & refurbishment

- Solid woven finger splicing

- Magnet belts

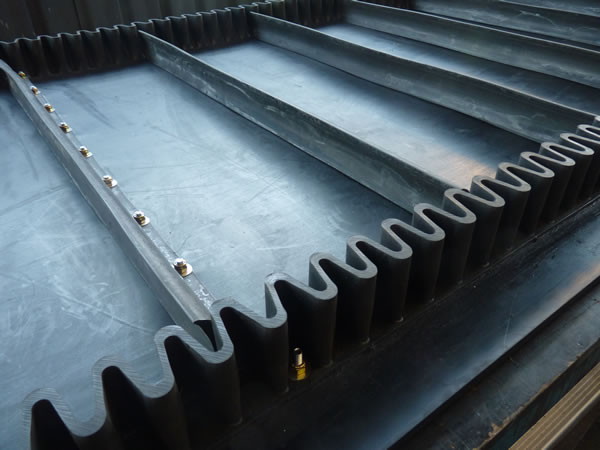

- Sidewall & cleated belt

- Bucket elevator belts

- Refurbishing vent tubes

Rubber Lining

Protection against corrosion, abrasion and wear.

Load Socks and Chutes

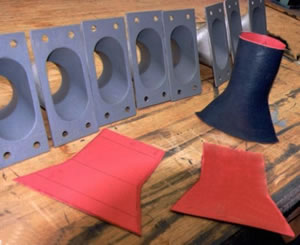

Our rubber lining division manufactures a wide range of chutes and liners for the concrete industry:

- Rubber sleeves

- Conical chutes

- Conical chutes with square or rectangular tops

Bin & Hopper Lining

Endless Belt is able to apply rubber lining both in the workshop or in-situ to various industrial components including:

- vibration chutes

- slides

- material transfer points

- truck bodies

- impact curtains

- bunkers

- silos

- chutes and

- filtering buckets